Atopol® Carbomer

Atopol range is a synthetic high molecular weight cross linked water soluble polymer of Acrylic acid, which is known as “Carbomer”/ “Acrylates polymers”. It is widely used in cosmetic, pharmaceutical and household industries. It is available in powder and liquid form, which is soluble in water, alcohols and glycols. Before neutralization, pH of Acrypol grade solution lies between 2.5 and 3.0.

Thickening

viscosity and flow property.

Suspending of insoluble ingredients like cosmetic beads.

To provide emulsification and stabilization of high content of oils and waxes.

Allows controlled drug release in solid dosage form in less concentration.

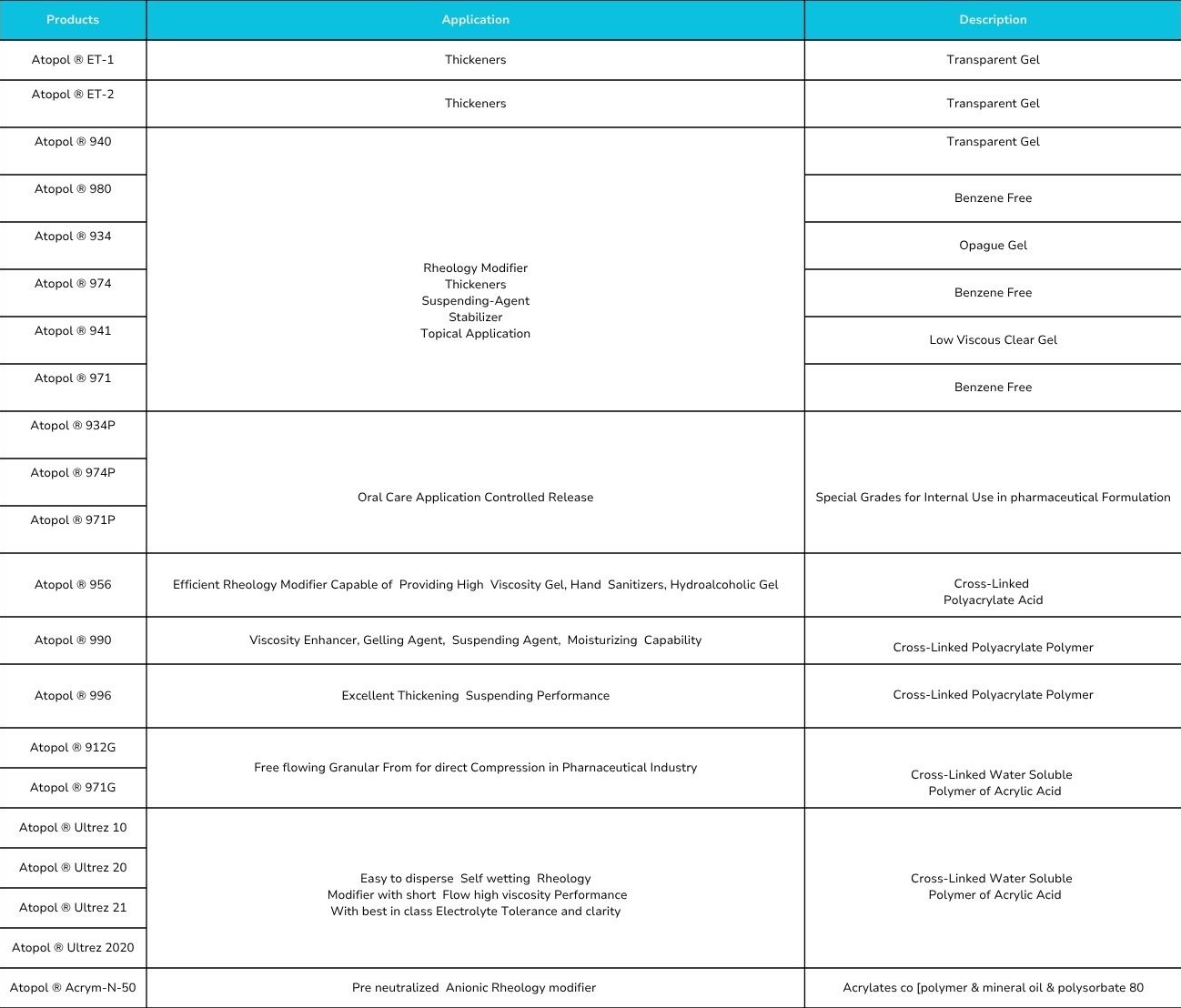

Our Grades

| Products | Application | Description |

| Atopol ® ET-1 | Thickeners | Transparent Gel |

| Atopol ® ET-2 | Thickeners | Transparent Gel |

| Atopol ® 940 | Rheology Modifier Thickeners Suspending-Agent Stabilizer Topical Application | Transparent Gel |

| Atopol ® 980 | Benzene Free | |

| Atopol ® 934 | Opague Gel | |

| Atopol ® 974 | Benzene Free | |

| Atopol ® 941 | Low Viscous Clear Gel | |

| Atopol ® 971 | Benzene Free | |

| Atopol ® 934P | Oral Care Application Controlled Release | Special Grades for Internal Use in pharmaceutical Formulation |

| Atopol ® 974P | ||

| Atopol ® 971P | ||

| Atopol ® 956 | Efficient Rheology Modifier Capable of | Cross-Linked Polyacrylate Acid |

| Atopol ® 990 | Viscosity Enhancer, Gelling Agent, Suspending Agent, Moisturizing Capability | Cross-Linked Polyacrylate Polymer |

| Atopol ® 996 | Excellent Thickening Suspending Performance | Cross-Linked Polyacrylate Polymer |

| Atopol ® 912G | Free flowing Granular From for direct Compression in Pharnaceutical Industry | Cross-Linked Water Soluble Polymer of Acrylic Acid |

| Atopol ® 971G | ||

| Atopol ® Ultrez 10 | Easy to disperse Self wetting Rheology Modifier with short Flow high viscosity Performance With best in class Electrolyte Tolerance and clarity | Cross-Linked Water Soluble Polymer of Acrylic Acid |

| Atopol ® Ultrez 20 | ||

| Atopol ® Ultrez 21 | ||

| Atopol ® Ultrez 2020 | ||

| Atopol ® Acrym-N-50 | Pre neutralized Anionic Rheology modifier | Acrylates co [polymer & mineral oil & polysorbate 80 |

Advantages

- Thickening efficiency High viscosity at low concentration

- Uniform performance Carbomer gives uniform viscosity performance, while natural gums vary in their performance

- Temperature Stability There is no significant effect of temperature on polymer

- Unaffected by aging Excellent shelf life

- Microbial Resistance Resists bacterial attack and does not support mould growth

- Versatility Although primarily used in aqueous systems with neutralization, it can also be used in solvent systems, with or without neutralization

- Elegance Smooth and luxurious feeling

Atopol polymers are dry, highly coiled acidic molecules. After dispersion in water, they begin to hydrate and partially uncoil. Maximum thickening can be achieved by converting the acidic Atopol polymer to a salt. It is easyily achieved by neutralizing the Atopol range with common base such as Sodium hydroxide (NaOH), Potassium hydroxide (KOH), Tri-ethanolamine (TEA), Ammonia (28%), Dilsopropanolamine, Aminomethyl Propanol (AMP), Trilsopropanolamine (TIPA), Ammonium hydroxide (NH₄OH), Arginine etc. It is prefererable to add strong bases previously diluted with water at a concentration not more than 10.0-20.0 % w/w.

Atopol range is a high molecular weight polymer. It cannot be absorbed by body, thus it is totally safe for human consumption. Test for toxicological tolerance shows that it does not have any pronounced, physiological action and is non-toxic.

Dermal irritation (in vitro test) – non irritant

Eye irritation (in vitro test) – non irritant

Skin sensitization (max. test) – non sensitizing

Atopol range is highly hygroscopic in supplied form, it contains maximum of 2.0% moisture. When exposed to open air at room temperature and 50% relative humidity, its equilibrium moisture uptake is 8.0%. All moisture uptake does not affect its efficiency but polymer with high level of moisture is more difficult to disperse and weigh accurately. So, Atopol polymers must be stored in a tightly closed container and away from direct contact with water and excessive humid conditions.

Atopol polymer’s efficiency will not get affected up to two hours at temperatures below 104°C. When it is exposed to excessive temperatures, it can be plasticized and lose its characteristics.

- Powder form – Five years retest from date of manufacturing in intact condition

- Liquid form – Two year from date of manufacturing in intact condition

Note: – Based on our testing, dry Atopol polymers should last for years if stored properly and protected from moisture and extreme temperature

- Powder form – 20 kg net in round fibre paper board drums with polyethylene liner

- Liquid form – 20 KG, 60 kg plastic carboys and 200 kg plastic drums